Across the UK and Europe, pathology laboratories are under growing pressure to prove, not just claim, ISO 15189:2022 compliance.

The latest ISO 15189:2022 revision places more weight than ever on traceability, data integrity, and risk-based thinking. Accreditation bodies, such as UKAS accreditation, now expect laboratories to demonstrate the chain of custody of every patient sample and environmental condition that could affect its quality.

For many labs, the pre-analytical phase (everything that happens before a sample reaches the bench), is still a weak spot. Manual logs, courier notes, and temperature charts can’t always capture the full picture. When an issue occurs, teams often spend hours or days piecing together fragmented records to explain what happened.

When audit readiness is no longer optional, that’s a problem.

The Pre-Analytical Blind Spot in ISO 15189 Compliance

It’s widely accepted that up to 70% of laboratory errors occur before analysis begins. *

Yet this stage remains one of the least digitised. Samples travel between collection centres, hospitals, and reference laboratories, often across large regional networks without continuous visibility.

If a temperature excursion occurs during transport, how quickly would you know, if at all?

If a courier route is delayed, can you see which samples were affected?

If an auditor asks for the journey history of a sample, can you produce a complete, timestamped record?

Most labs can’t answer “yes” to all three. Manual or partially automated systems can’t provide the level of contextual data that modern accreditation requirements demands.

What ISO 15189 and UKAS Really Want to See

ISO 15189:2022 doesn’t just ask for records it asks for evidence.

Clause 5.4.2 requires laboratories to ensure that “the transport of samples shall be designed to maintain the integrity of the sample and the safety of the carrier.”

Clause 8.4 requires that “records be retained to demonstrate that quality and competence requirements have been met.”

In the UK, laboratories are accredited by UKAS (the United Kingdom Accreditation Service), which assesses compliance with ISO 15189 laboratory requirements. Across Europe, the same standard is recognised by other national accreditation bodies such as DAkkS in Germany, COFRAC in France, and ENAC in Spain, all operating under the European Cooperation for Accreditation (EA) framework.

While the names differ, the principle is identical: laboratories must be able to demonstrate traceability, data integrity, and competence through objective, verifiable evidence.

In other words, it’s not enough to have a temperature log and a courier sheet.

Labs must be able to show, with certainty, where a sample was, when it was handled, under what conditions, and who was responsible at each step.

This level of sample traceability is difficult, if not impossible, to achieve manually.

That’s where automated sample tracking can make a measurable difference.

Turning Digital Traceability and Sample Tracking into a Strength

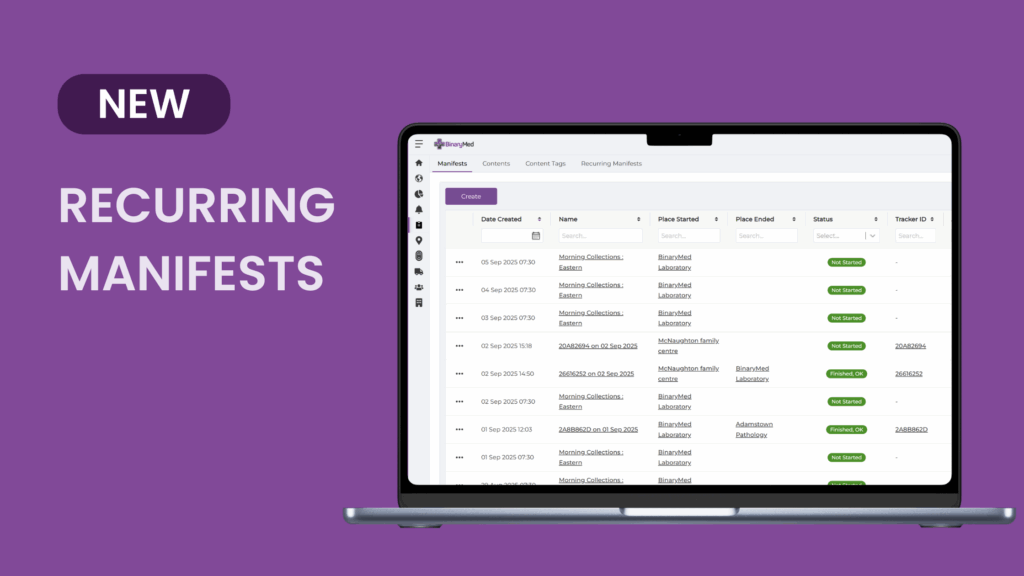

BinaryMed’s Cicada Voyager sample tracking system is a compact, battery-powered IoT device that passively records a sample’s location, temperature, movement, and light exposure throughout transit. It’s placed inside a shipment container and begins transmitting real-time monitoring data automatically via low-power 5G networks to the Binary Cloud platform, no manual scanning, gateways, or apps required.

The result is a live, tamper-proof audit trail of every journey.

Labs and logistics teams can see where each consignment is, confirm temperature stability, and receive instant alerts if something goes wrong.

Instead of spending hours reconstructing the story of a sample after an incident, teams have continuous, real-time visibility.

Every event, pickup, delivery, delay, and temperature breach is logged automatically and linked to the relevant manifest or courier route.

That’s not just operational convenience, it’s compliance confidence.

How Real Data and Automated Sample Tracking Build Confidence in Accreditation

Traditional laboratory compliance efforts often stop at documentation. Logs are filled out, records are filed, and the process is technically complete.

But ISO 15189 accreditation and accreditation bodies across Europe expect laboratories to go further, to demonstrate that their systems actively protect sample integrity and patient outcomes.

That’s where real-time lab sample tracking changes the game.

By continuously capturing real-world data on temperature, location, and handling, labs can replace assumptions with proof. Every movement and environmental change becomes part of a verifiable audit trail, building confidence for both internal teams and external assessors.

Instead of relying on retrospective records, labs can now show exactly what happened and when.

It’s not about ticking boxes, but about being able to stand behind every test result with objective, data-driven evidence.

When an auditor asks, “How do you know your transport process maintains sample integrity?”, labs using automated tracking can simply open their dashboard and show it in seconds.

That shift from paper-based to data-driven compliance doesn’t just simplify audits; it transforms the entire quality culture.

Teams gain clarity, risk is reduced, and accreditation readiness becomes something lived day-to-day rather than prepared for once a year.

From Reactive to Proactive ISO 15189 Compliance

One of the biggest benefits UK labs report is speed of response.

With real-time alerts, incidents that once took days to investigate are now identified and addressed within minutes.

Temperature excursions trigger instant notifications, so samples can be triaged or recollected before test results are compromised.

This proactive compliance capability transforms how labs manage quality. Instead of waiting for non-conformances to surface during an audit, they can detect and correct issues in real time, aligning perfectly with ISO 15189’s principle of continual improvement.

Why Real-World Data Matters for ISO 15189 and UKAS Accreditation

Accreditation bodies like UKAS are moving towards evidence-based compliance. They want to see how data integrity informs risk management, quality improvement, and patient safety.

Automated sample tracking provides that foundation. It captures the real-world conditions surrounding every sample, offering irrefutable proof that pre-analytical risks are identified, controlled, and continuously reviewed.

This helps laboratories demonstrate alignment not only with ISO 15189 but also with broader quality frameworks like ISO 17025 and ISO 9001.

The Path to Simplified ISO 15189 Accreditation

Preparing for ISO 15189 accreditation doesn’t have to mean more paperwork.

By automating sample traceability, labs can reduce manual processes, eliminate blind spots, and ensure that every audit is backed by high-integrity data.

Compliance automation becomes part of daily operations, not a scramble before inspection.

BinaryMed gives labs the real-time visibility and confidence they need to meet modern accreditation expectations across the UK and Europe.

Ready to see how digital traceability can strengthen your compliance? Request a demo of BinaryMed’s sample tracking solution or talk to us to experience how effortless ISO 15189 and UKAS readiness can be.

* Plebani M. Errors in clinical laboratories or errors in laboratory medicine? Clin Chem Lab Med. 2006;44(6):750-759.